In today’s fast-paced world, consumers expect high-quality products readily available on store shelves. The soap industry is no exception. But how can manufacturers meet this ever-growing demand while maintaining profitability? Manually packaging each soap bar can be a time-consuming bottleneck, hindering production efficiency and impacting your ability to meet market demands. This is where flowpack machines come in – offering a powerful solution to streamline the soap packaging process and significantly boost production efficiency. Imagine a continuous flow of your beautifully crafted soap bars effortlessly gliding into sleek, sealed packages. Flowpack machines make this a reality, transforming soap packaging from a labor-intensive process into a smooth, automated operation. Let’s delve deeper into how these machines can revolutionize your soap production line, increase efficiency, and help your brand thrive in the competitive marketplace.

What is a Flowpack Machine?

A flowpack machine, also known as a horizontal form-fill-seal machine or a flow wrapper, is a versatile piece of packaging equipment. Imagine a continuous flow of soap bars gliding effortlessly into sleek, sealed packages. That’s the magic of a flowpack machine. It utilizes a continuous roll of flexible film, typically plastic or laminate, to form a pouch or bag around the product. The product, in this case, being your beautifully crafted soap bars. The machine then fills the formed pouch with the soap bar and seals it using heat, ultrasonic waves, or cold sealing depending on the chosen material and product characteristics.

Their Benefits for Soap Production

Flowpack machines offer a multitude of benefits for soap manufacturers, making them a strategic investment for increased efficiency and profitability. Let’s explore some key advantages:

- Faster Packaging Speeds: Traditional manual packaging methods can be time-consuming and limit production output. These packaging machines, on the other hand, operate at high speeds, effortlessly packaging multiple soap bars per minute. This translates to a dramatic increase in throughput, allowing you to meet market demands more efficiently.

- Reduced Labor Costs: By automating the packaging process, flowpack machines significantly reduce the need for manual labor. This not only frees up your valuable workforce to focus on other crucial tasks like quality control and product innovation but also translates to reduced overall production costs.

- Improved Consistency: Maintaining consistent, high-quality packaging is essential for brand image and customer satisfaction. Flowpack machines ensure consistent and reliable packaging every time. Precise heat sealing and film control guarantee a professional finish, minimizing package defects and ensuring your soap bars are presented in a visually appealing and secure manner.

- Seamless Integration: Flowpack machines are designed for easy integration with existing soap production lines. This minimizes disruptions to your current workflow and allows for a smooth transition from production to packaging, streamlining the entire process.

Types of Machines for Soap Packaging

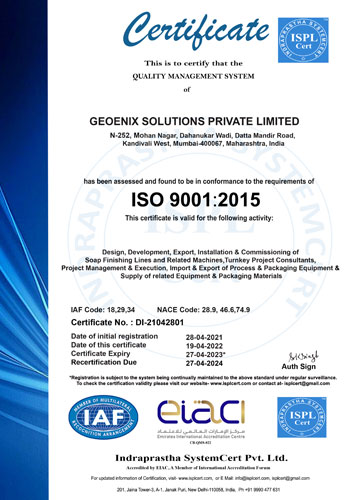

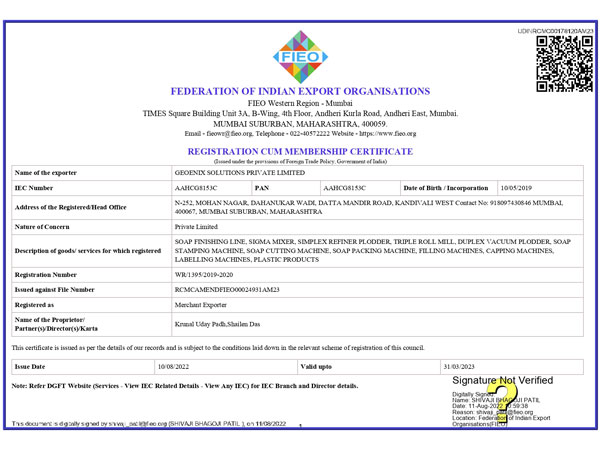

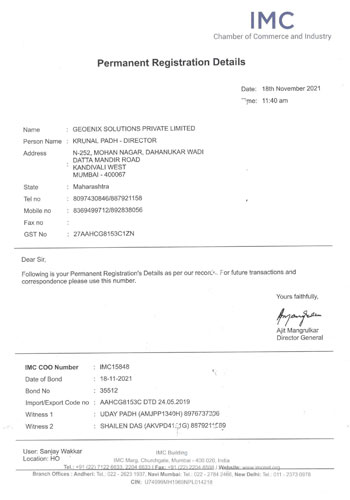

Here at Geoenix, we understand that soap manufacturers have diverse needs. That’s why we offer a variety of machines to cater to specific applications:

- Mechanical Machines: These machines are a cost-effective solution for basic soap packaging needs, offering reliable performance and ease of operation, ideal for smaller production runs.

- Servo Based Machines: For high-speed production environments and complex packaging requirements, servo-based machines are the perfect choice. These advanced machines offer superior speed, precision, and flexibility, allowing you to efficiently package a wider range of soap shapes and sizes.

Investing in the Future of Soap Production

Investing in these packaging machines is a strategic decision for soap manufacturers looking to elevate their production game. These versatile machines offer a powerful one-two punch: increased efficiency and reduced costs. By automating the entire packaging process, flowpack machines eliminate the need for manual labor, a significant factor in streamlining production and boosting output. This translates to a major increase in the number of soap bars packaged per minute, allowing you to meet and exceed market demands with greater ease. Furthermore, the reduction in manual labor translates to significant cost savings.

Not only are you freeing up valuable human resources to focus on other crucial aspects of your business, but you’re also minimizing the potential for human error during the packaging process. Flowpack machines ensure consistent, reliable packaging every single time, guaranteeing a professional finish and minimizing package defects. This not only enhances the visual appeal of your soap bars on store shelves but also reduces wasted materials and the need for re-packaging. Ultimately, investing in flowpack machines empowers your brand to operate more efficiently, reduce costs, and deliver a consistently high-quality product to your customers, all of which contribute to a thriving and successful business in the competitive soap market.

Ready to Take Your Soap Production to the Next Level?

At Geoenix, we are passionate about providing soap manufacturers with the best tools and technology to succeed. Contact us today to explore our selection of high-performance flowpack machines. Our experts will help you identify the ideal machine for your specific needs and production goals. With Geoenix as your partner, you can streamline your soap packaging process, accelerate your production, and ensure your beautiful soap bars reach consumers in a way that reflects the quality and care you put into crafting them.